The Battery and Sensor Test Center on the Campus for Battery Safety Germany is operated with the TU Clausthal, along with the Energy Research Center of Lower Saxony and the Fraunhofer Heinrich-Hertz-Institute. This embodies the research infrastructure for the testing of high-powered battery systems which in respect to their performance is unique on a national level. With this infrastructure the partners are well-quipped to deal with a future in which batteries for busses and trucks are the state of technology and the charging of batteries with 500 kW is no longer seldom.

Batteries, especially for electric mobility, have to meet stringent requirements in regard to energy and power density which is why highly integrated solutions are essential. High heat densities resulting from high energy and power densities need to be dissipated and require a well thought through thermal management. Especially in critical areas, such as the fast charging of batteries or highly dynamic loads with simultaneous high or low surrounding temperatures, high requirements have to be met by the batteries and the thermal management system. A further area of interest is the behavior of batteries in extreme situations (i.e. accidents).

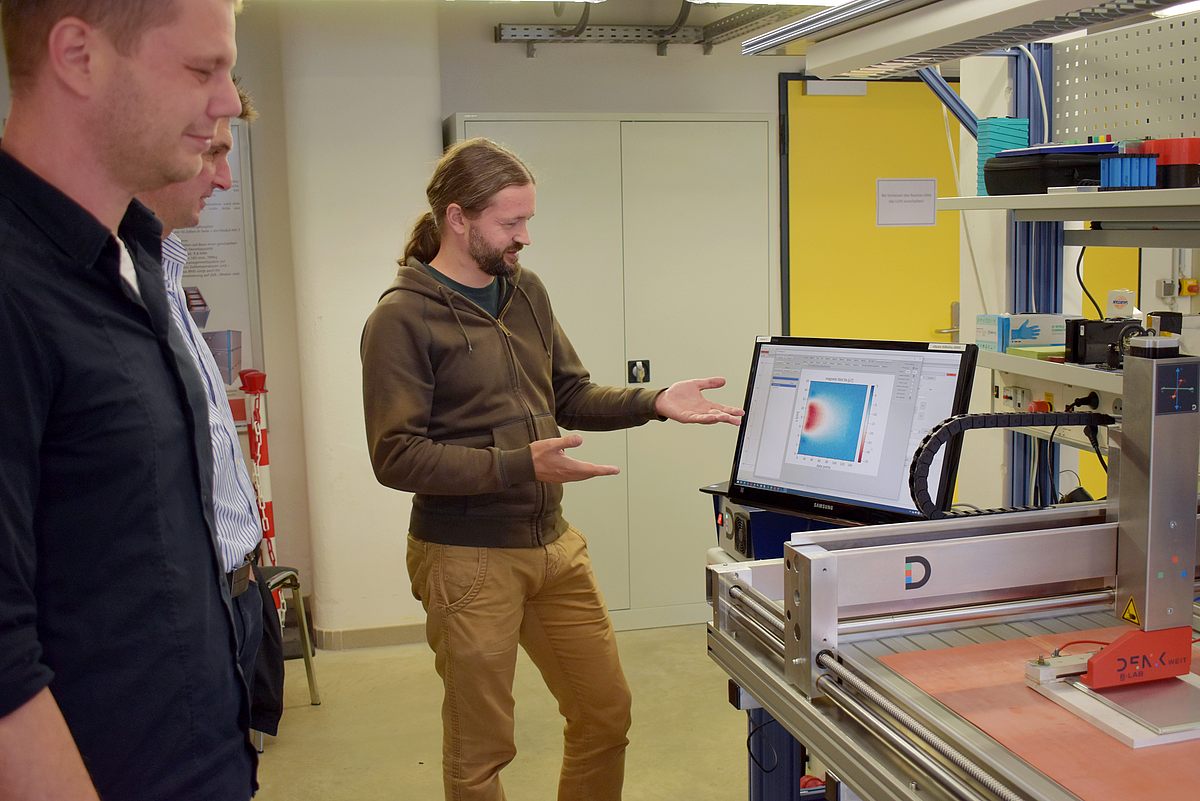

With the innovative research surroundings provided by the Battery and Sensor Test Center, the expertise of the partners concerned with the characterization and investigation of batteries in respect to their electric and thermal properties under extreme conditions are bundled. Currently, the following portfolio of test benches with corresponding load scenarios can be provided:

Power Test Bench

The power test bench enables electric load tests up to 1000 V and 1200 A (simultaneously) in which a fire emergence is tolerated.

With the power test bench, a unique testing environment was established. The test bench possesses current slope-up times of 10 to 90 % in less than 3 ms and is therefore suitable for highly dynamic requirements. Furthermore, the test bench is divisible flexibly onto two channels with 600 kW power each.

The metering infrastructure (see also below: measurement sensors) enables a dynamic recording of data and high regulation accuracy of the test bench to less than 0.1 %.

Cost-Effective Sourcing of Power with Buffer Battery

The high sourcing of power by the test bench can be realized via a lead buffer battery, so that the loading of the grid is minimal and high energy/power prices can be avoided. In order to do so, a battery with 400 cells and 800 kWh calorific value was installed which can provide up to 960 kW power for approximately 20 minutes.

Measurement Sensors: Electric Measuring System

The test bench includes a voltage metering system with 320 channels with a total sampling rate of 20 kHz over 20 channels each. All channels have been galvanically isolated from each other up to 1000 V. The measuring range can be divided into decades of 10 V to 1000 V in four sectors. This system enables the individual monitoring of a battery with up to 320 cells simultaneously. Further current and temperature measurement values can be recorded as well, due to freely configurable AD-converters.

Measurement Sensors: Fiber Optic Temperature Metering System

A fiber optic temperature metering system enables the evaluation of almost any number of measuring points simultaneously which can be integrated flexibly into battery systems or other test items. A great advantage of sensors is that due to their small size (about the width of a hair) they can be retrofitted to almost any existing system without great constructive alternations. Furthermore, the sensors are resistant to electromagnetic fields which often cause noisy data in battery systems subjected to dynamic loads. The sampling rate of the system lies at min. 1 Hz and the temperature accuracy at ±1 °C. While a temperature range of -30 to 300 °C is state of the art, temperature ranges up to the melting point of the fibers are still being developed.

Climate Chamber

A climate chamber enables the investigation of larger vehicle batteries under controlled climatic conditions, with a dimension of 3.0 m x 3.0 m x 2.3 m. The focus is set not only on temperature influences, but also the corresponding air humidity. The humidity can be regulated from 5 to 95 % and the temperature from -30 to 85 °C, with a rate of temperature change of 1 K per minute. The climate chamber is flame-retardant and is in possession of a nitrogen extinguishing medium.

Cell and Module Test Benches

For the examination of single cells and modules, the battery test center is equipped with a battery test station containing 16 channels with 6 V and 25 A each, as well as a channel with 6 V and 400 A. Additionally, 8 further channels can be parallelized arbitrarily to a single channel from 25 A to 200 A. Also included are two fire-protected, water-cooled test chambers. Combined with another module test station (100 V, 100 A) at the EFZN, as well as the power test bench, all battery sizes can be covered in the test field.

Furnace

Two furnaces with inner dimensions of 3.0 m x 3.0 m x 2.5 m as well as 1.5 m x 1.5 m x 2.5 m provide an explosion-proof testing environment for extreme tests, even for larger battery systems. In the event of an accident, the burn-off of the whole battery is enabled whereby the remaining harmful gases are filtered from the exhaust flow via an exhaust gas purifier. The furnace is temperature stable up to temperatures over 1200 °C and is equipped with a heating capacity of over 2 MW. A corresponding control system enables the running of, for example, uniform temperature curves which are often required for material testing. Additionally, admission tests (e.g. fuel fire test) can be performed independently of external weather conditions.

Gas Measuring System

Various gas measuring systems allow the qualitative and quantitative verification of relevant combustion gases in the furnace on a material level. Aside from optical gas measuring systems, the Battery and Sensor Test Center also provides mass spectroscopy and further analysis procedures in cooperation with the CUTEC environmental institute.

Conclusion: With the previously mentioned components, as well as additional accessories such as current and voltage metering technology and thermographic cameras, a nationwide unique and flexible testing infrastructure has been made available.