With the increasing development and usage of most diverse battery storage technologies, researchers are continuously taking on new challenges. Especially the novel high energy / power storages for electricity for mobile and stationary applications are seen as major contributors to the advancement and success of the energy transition.

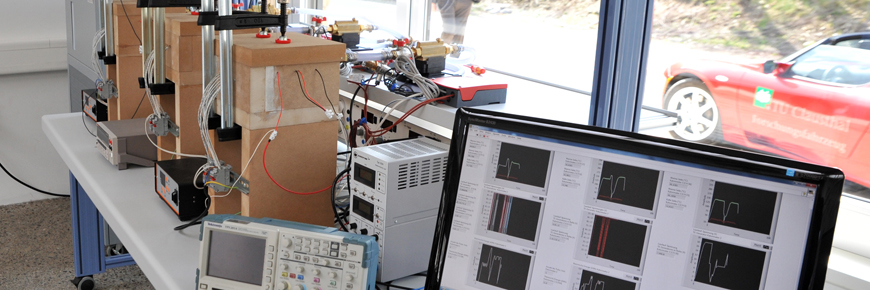

On the Campus for Battery Safety, research projects for the safe application of batteries are being conducted, from small half cells to larger battery systems. Thanks to the especial bundling of expertise in electro-chemical process engineering, sensor technology and further engineering disciplines, complex problems can be addressed.

In the field of electric mobility, for example, larger driving ranges of electric vehicles are anticipated. Therefore, compact batteries with high capacities, as well as fast and secure charging technologies are needed. For this reason, one of the ambitious goals of the Campus for Battery Safety is to charge a driving range of 500 km in just 10 minutes with 100 % renewable energy and minimal grid- and battery load.

A battery has to function safely and reliably in any situation and cannot combust even under extreme conditions. To ensure this, a three stage safety concept was designed. This concept is being continuously adapted and developed further to fit current issues. Aside from highly precise and innovative sensor technology, the concept integrates and develops a variety of operating strategies and safety mechanisms as well.

A focus of further research projects is set on the development of metal-air batteries which are especially relevant for the breakthrough of electric mobility. The energy density of these batteries is much higher than that of lithium batteries, as the systems procure oxygen from the surrounding air and emit it again when charging. When discharging, “breathing” batteries change chemically irreversibly and currently cannot be re-charged durably. Also, the current charging technologies aren’t sufficiently developed and charging at too high speeds changes the electrode materials due to the generated heat which can lead to the bursting of the batteries. A solution could be a customized cooling process.